AAA Suspension Load Assist Airbag Kits FAQs

AAA Suspension FAQs

Who are AAA Suspension?

The team at AAA Suspension are suspension specialists and have been looking after customers with air suspension needs since the 90's. We are a family owned business based in Melbourne and pride our selves for excellent product knowledge, great service and support.

We also have a keen interest in our local economy and evironment. Apart from making all of our brackets here at our Melbourne premise, we employ locals who were otherwise without work displaced by Covid and now we are carbon negative. We fitted 70 solar panels and 4 large batteries so now we give power to the grid and no longer pay for electricity. Also we re-home any packaging material we receive and when we buy new packing material we make sure it is biodegradable.

Airbag Kits

Load Assist airbags sit between the chassis and axle to assist with carrying loads. Just add more air until you reach the ride height you want no matter how heavy your load. And when you don't have a load just let the air out of the bags and you are back to having soft suspension and a comfortable ride. If you get heavy springs you cant go back to soft when unloaded and most people find their heavy springs are still not heavy enough anyway. If you see yourself in this predicament then you really should consider air springs to assist your old suspension.

Here are just a few examples...

- Slide on campers - heavy when the camper is on but light when the camper is off.

- People towing vans and trailers need air springs when they are towing but their factory suspension is ideal when they are not.

- Some contractors cart fuel, water firewood and they get heavily loaded but light when empty.

- Tradies cart different tools and equipment to different jobs.

With air springs all of these guys can change the load capacity of their suspension to suit their needs.

Make towing safer by loading more weight to the front of the van or trailer and just pump up the bags a bit to handle the bit of extra weight on the draw bar. They are rated to still be effective with 2.5t over the back axle which in most cases is way more than you should be carrying and just goes to show the bags are up for what ever you throw at them. Heavy duty leaf springs are rated at say +400 etc and that's only 400Kg. Our air springs are 5 - 6 times more capable than that. And still be soft when unloaded.

These will not impact your insurance, don't present any legal issues nor do they need to be engineered. When fitting these bags you are not changing your old suspension nor increasing your GVM allowances.

When carrying a load the typical pressure range is 25psi to 50psi which is pretty much what you would run in your tyres, right? Same same ! The good thing about air bags is just keep adding more air until you reach your desired ride height and comfort no matter the weight. You can't hurt the bags because they can go to like 1000 psi.

The Air Bags replace and become your new bump stop. Even if you have no air in them the bag compresses and the sidewalls are such that you still have a rubber bump stop. The end plates are still an inch apart on full compression so they do not strike each other. As such we don't need internal bump stops. Watch other more expensive brands who state their warranty is void if run empty and that's because their end plates strike each other and chew at the inside of the bags eventually causing failure - not with our style of bag. It's ok to run these flat. Note that because they are your bump stop it's also good to have a few pound in the bags even when not carrying a load to cushion your bump stop and it makes for a more sporty ride too.

Here's where AAA Suspension lead the way and beat the other brands....

AAA Suspension brackets are all 100% made by us here in Australia. Other brands make their brackets overseas and not only is that un-Australian but when they run out they can run out for months. It also means they can't customise brackets for customers. We are the only air suspension sellers who actually make the kits they sell.

AAA Suspension has been approved and licensed to use the Made in Australia logo.

AAA Suspension have a massive 4WD knowledge base and their kits do not fall short. Some other brands claim to suit 2" lift when they barely reach standard height. At AAA, we offer height options and can even tailor make custom kits.

AAA Suspension kits use heavier steel components. Our engineer says not only are they stronger but we can crank up the welder and get deeper more penetrating welds.

The manufacture and design of AAA Suspension kits has been guided by automotive engineers who not only specify materials and designs but specify where and how to weld so as not to compromise the integrity of the steel. The others clearly got that wrong as they weld across the arms instead of with them in their brackets.

Others use imperial 1/4" air line and NPT threads whereas AAA Suspension use metric 6mm and BSP threads ... means parts are readily replaceable anywhere if needed while on a big trip. Even Bunnings sell 1/4" BSP stuff.

AAA Suspension air fittings come pre-fitted to end plates with high pressure gas sealant.

AAA Suspension kits come with 6 metres of air line and its high flex, super strong and meets all the safety standards.

Every bolt and washer in an AAA Suspension kit is stainless steel so wont rust.

In-Cab Kits

Our Digital In Cab Compressor Kit has a twin LED display and electric push button switches beside the gauge, operating 4 electronic valves outside the car - 1 up and 1 down for each bag. This means no air lines inside the car, and a reduced risk of springing an air leak with a lot less air fittings. The ability to inflate and deflate each bag even while driving is a huge advantage. It means you can get the pressures just how you like them depending upon your load or the driving conditions. Contractors who's load changes weights as the day goes on can quickly adjust the bags as they go with the tickle of a button.

Testing

Our compressors have been extensively tested both in our workshop, and in customer vehicles. For testing information, click here.

In-Cab Kit Products

Large in-cab kit

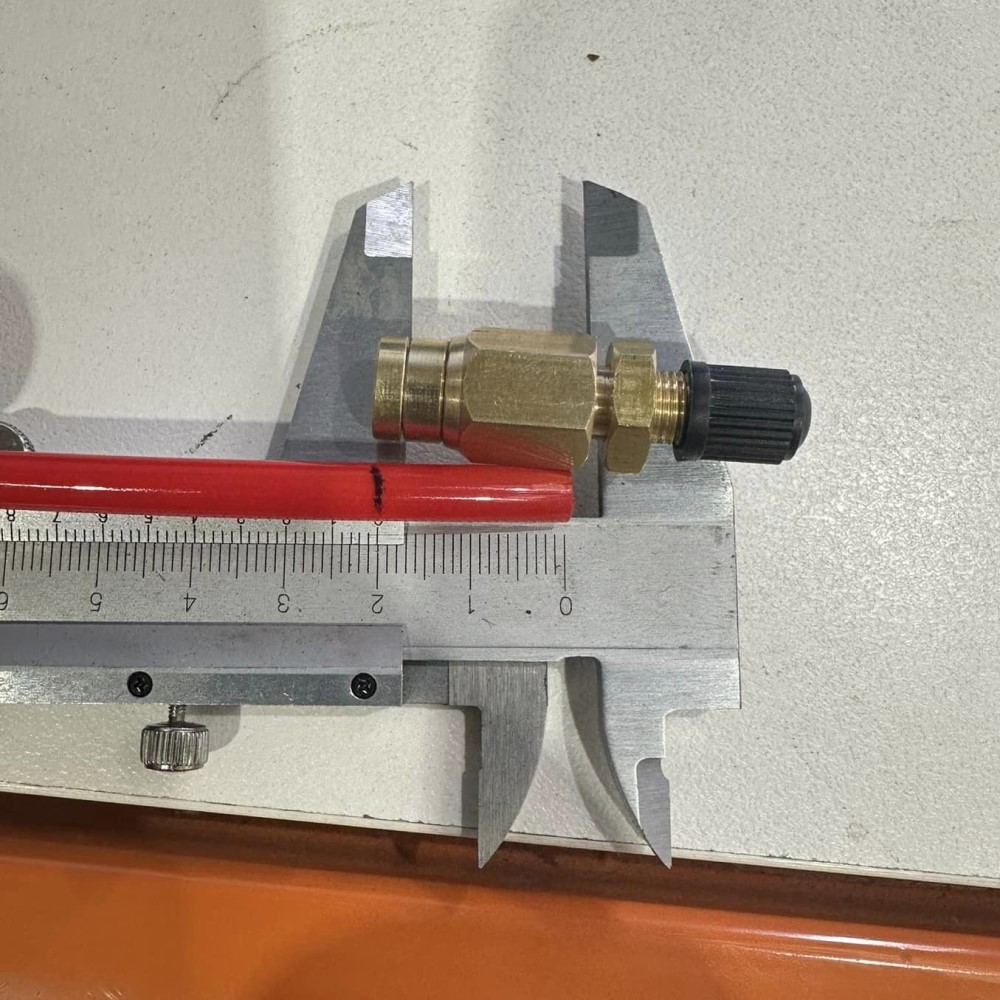

Installing Schrader Valves:

.jpg)

How to Test for Air Leaks

How to Align Brackets

How to Tighten Airbag Bolts

How to Install Push-in Air Fittings

How to Install new Bushes

How to Realign Compressor Head